Nowadays, how to develop and utilize renewable energy has become a pressing task for the world.

As a leader in power and automation technologies, ABB enables utility and industry customers to improve performance while lowering environmental impact. Meanwhile, the ABB Group pays much attention to renewable energy especially the wind power, and consider it as the key growth drive of power and automation business.

ABB has contributed to many local wind power projects in China with leading technologies, quality products and attentive services. For example. ABB provided converters to the “Three Gorges Wind Power Project” in Jiuquan, Gansu province, the Jiangsu coastal Wind Farm, the East Inner Mongolia Wind Farm, and the Zhangbei Wind Farm. Though influenced by the financial crisis in 2009, ABB has still made an impressive growth in Chinese wind power business, 125% increase over the previous year.

Recently, ABB has been launching a new slip ring generator series designed to fit most present 1.5 – 2.0 MW doubly-fed turbines. In order to know more details about this new product, we were hornered to have an interview with Riku Kytomaki, company president of ABB.

When first met Mr. Riku Kytomaki, the new head of ABB High Voltage Electric Co. , in the meeting room, we felt a little surprised to find that he was much younger than I imagined and was very kind. I was told that Mr. Riku Kytomaki has been working in ABB for 16 years, and once worked in Finland, Germany and Switzerland. In June 2009, Mr. Riku came to China and took over the ABB high-voltage motor business in April 2010. Since then, he has started his another legendary journey in China with his Chinese team.

nload="javascript:if(>500)=500" align=center border=0>

nload="javascript:if(>500)=500" align=center border=0>

Mr. Riku Kytomaki

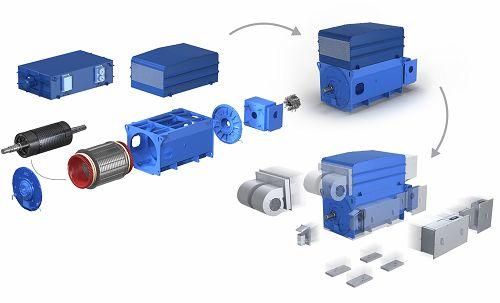

Riku Kytomaki said the new generators featuring an enhanced rotor design and modular interface, which made the product suitable to most turbines used today as well as to all kinds of land based and off-shore wind farm. With a patented rotor design, the new product can withstand overspeed and voltage peaks, and reaches an increased insulation level at 2.5 kV and a maximum overspeed up to 3,000 revolutions per minute. The reliable ABB slip ring design used in the new generator series is based on more than half a century of experience in building slip ring motors for many demanding applications. The product, maintaining a leading position in terms of both technology and performance in the global market, will be introduced for local production in China soon after its release.

nload="javascript:if(>500)=500" align=center border=0>、

nload="javascript:if(>500)=500" align=center border=0>、

the new standard series of slip ring generator

nload="javascript:if(>500)=500" align=center border=0>

nload="javascript:if(>500)=500" align=center border=0>

the structure of new standard series of slip ring generator

nload="javascript:if(>500)=500" align=center border=0>

nload="javascript:if(>500)=500" align=center border=0>

one of the highlights: the enhanced rotor design

It’s well known that there is a fierce competitive in the wind power industry wether in the Chinese or global market. While ABB can maintain its leading position for years. Riku Kytomaki said several factors contributing to ABB’s success.

First of all, ABB has very broad product portfolios, including wind generators, converters, air circuit breakers, and contactors et al. Furthermore, ABB provides electrical products for all wind power subsystems, including the electrical drivetrain system, the grid connection system, the turbine control and protection system, the pitch and yaw systems, the electrical protection and disconnection system, lighting protection, the hydraulic and cooling system, and auxiliary systems.

Secondly, ABB offers leading technologies of both doubly-fed and permanent magnet technology for wind turbines. In wind power applications ABB combines its expertise in conventional synchronous generators and new permanent magnet technology. ABB also utilizes technologies which are already tested in other motor and generator applications. permanent magnet technology, which is. Nowadays, very few Chinese manufacturers can master the permanent magnet technology while ABB has applied it to many industries.

The last but not least, ABB supplies optimal service for the customers of wind power sector. The company offers a full spectrum of tailored life cycle services, including pre-purchase engineering, installation and commissioning, technical support, online and classroom training, preventive maintenance, spare part kits, retrofitting and refurbishment, to help customers operate at optimum levels.